The use of biological systems for future sustainable production of commercially valuable materials is gaining momentum spearheaded by synthetic biology, green synthesis of functional and adaptive materials, and, more recently, material farming. Material farming harnesses "already in place" optimized biological strategies and mechanisms from higher organisms that act as biofactories with chemically synthesized molecules carrying desired functionalities to yield new materials with tailored properties. We are particularly interested in applying the material farming concept to cotton (Gossypium hirsutum, Upland cotton) to biologically redesign fibers' properties.

Why cotton? Cotton plays an important role in many countries' economies (e.g., India, Burkina Faso, Uzbekistan), with 250 million people around the globe working in cotton-related industries. The cotton-based textile industry is expected to reach US$ 223 billion by the year 2025. Yet, cotton growth and chemical post-processing (i.e., dyeing) are unsustainable in the long term. So, material farming can serve as a sustainable future alternative.

As an initial proof-of-concept, we combined chemical synthesis of glucose derivatives and in vitro cotton growth cultures to demonstrate in situ biological fabrication of cotton cellulose fibers with built-in properties such as fluorescence (Figure 1), supermagnetism, or increased hydrophobicity.

Figure 1. Biologically-produced fluorescent cotton fibers from cotton ovules.

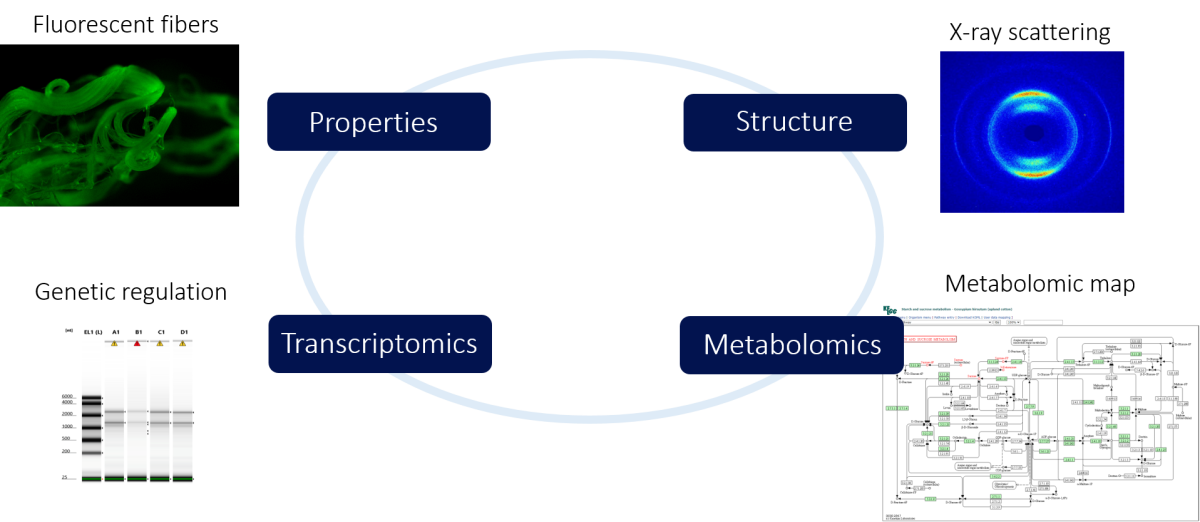

In recent years, we have been exploring hierarchical biochemical-strucural relations of cotton fiber modification using a combination of transcriptomic (RNASeq) and metabolic profiling, and physical characterization of the fiber structure (Figure 2) at sequentially increasing levels of complexity (Figure 3).

Figure 2. Roadmapt to explore the hierarchical relations between biochemistry and structure of cellulose fiber modifications in cotton.

Figure 3. Schematic representation of the complexity ladder.

Collaborators:

Prof. Peter Fratzl - Max-Planck Institute of Colloids and Interfaces, Germany

Dr. Michaela Eder - Max-Planck Institute of Colloids and Interfaces, Germany

References:

1. Natalio F, Fuchs R, Cohen SR, Leitus G, Fritz-Popovski G, Paris O, Kappl M, Butt HJ. Biological fabrication of cellulose fibers with tailored properties. Science. 2017 Sep 15;357(6356):1118-22. Feature in Nature Chemical Biology (https://www.nature.com/articles/nchembio.2505) and FORBES magazine (https://www.forbes.com/sites/samlemonick/2017/09/14/this-cotton-is-grown...)

2. Natalio, F., 2019. Future Perspectives on Biological Fabrication and Material Farming. Small Methods, 3(1), p.1800136.

3. Natalio, F., 2020. Tracking the Biological Incorporation of Exogenous Molecules into Cellulose Fibers with Non‐Radioactive Iodinated Glucose. Israel Journal of Chemistry, 60(12), pp.1197-1207.