Overview

The term ‘molecular beam epitaxy’ (MBE), introduced in 1970 by A. Cho in Bell laboratories, where the first prototype of the MBE machine was developed, describes a process of epitaxial crystal growth that is facilitated as a result of atomic and/or molecular beams propagating in vacuum and condensing on a heated crystalline surface. The growth relies on kinematic processes on the surface, such as migration, adsorption, desorption, dissociation and incorporation. Clearly, the process of growth requires real-time in situ monitoring and control, to assure the stoichiometry of the epitaxy. The MBE systems are usually composed of several ultra-high vacuum (UHV) chambers with means for sample transfer between the different chambers, and a growth chamber. The latter is equipped with appropriate pumping facilities, sources of molecular or atomic beams, each functions either by evaporation or sublimation, substrate manipulator with a rotatable wafer holder, wafer heater and various in-situ characterization tools.

The term ‘molecular beam epitaxy’ (MBE), introduced in 1970 by A. Cho in Bell laboratories, where the first prototype of the MBE machine was developed, describes a process of epitaxial crystal growth that is facilitated as a result of atomic and/or molecular beams propagating in vacuum and condensing on a heated crystalline surface. The growth relies on kinematic processes on the surface, such as migration, adsorption, desorption, dissociation and incorporation. Clearly, the process of growth requires real-time in situ monitoring and control, to assure the stoichiometry of the epitaxy. The MBE systems are usually composed of several ultra-high vacuum (UHV) chambers with means for sample transfer between the different chambers, and a growth chamber. The latter is equipped with appropriate pumping facilities, sources of molecular or atomic beams, each functions either by evaporation or sublimation, substrate manipulator with a rotatable wafer holder, wafer heater and various in-situ characterization tools.

The most distinct feature of high mobility MBE systems is the use of extremely high speed vacuum pumps in the growth chamber. Specially designed large diameter cryopumps are employed, including additional liquid nitrogen cooled stage, which permits high-temperature bakeout of the pump body. Interestingly, such a powerful pumping systems play little role during the growth process itself; their major function is to enable MBE system preparation, which includes the bakeout of the whole system and careful outgassing of the source materials, which are the most important constituents in obtaining high quality, low impurity concentration epitaxial layers. The preparation can be considered successful if vacuum level in a range of 10-12 Torr is achieved while the effusion cells are idling.

Our equippment

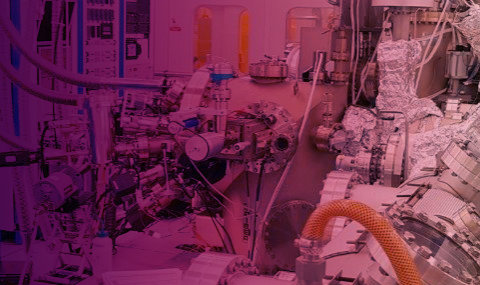

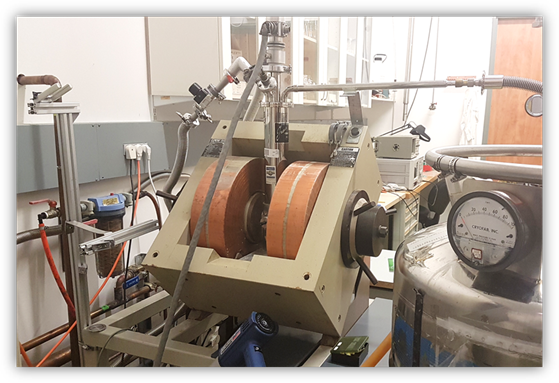

MBE-32 system from RIBER (France). Installed in 1991.

MBE-32 system from RIBER (France). Installed in 1991.

UHV Pumping: TM400 & TM150 CVI Torr Master® pumps from PHPK TECHNOLOGIES Inc (USA).

Materials sources from RIBER & Veeco (USA).

Materials: Ga, Al, In, Si, As, Sb.

Basic UHV pressure < 5 × 10-12 Torr

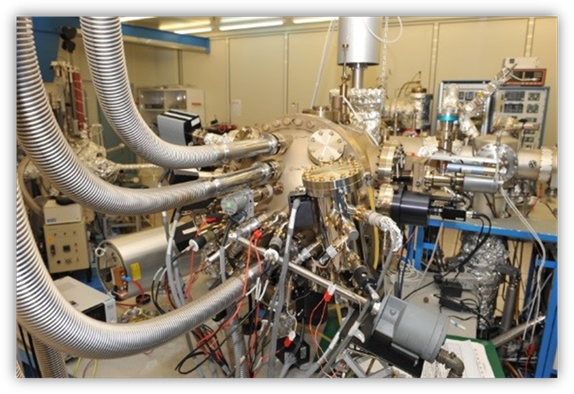

Compact 21 HM system from RIBER. Installed in 2008. Specially designed by the Weizmann MBE group & Riber engineers for ultra-high purity material growth.

Compact 21 HM system from RIBER. Installed in 2008. Specially designed by the Weizmann MBE group & Riber engineers for ultra-high purity material growth.

UHV Pumping: 2 × TM400 CVI Torr Master® pumps from PHPK TECHNOLOGIES Inc.

Materials sources from RIBER, Veeco & MBE Komponenten (Germany).

Materials: Ga, Al, Si, As.

Basic UHV pressure < 2 × 10-12 Torr

The MBE laboratory is supported by several essential post-growth characterization tools including variable temperature Hall measurement system, X-ray high resolution diffractometer, C-V & I-V parameter analyzers, etc.

The MBE laboratory is supported by several essential post-growth characterization tools including variable temperature Hall measurement system, X-ray high resolution diffractometer, C-V & I-V parameter analyzers, etc.

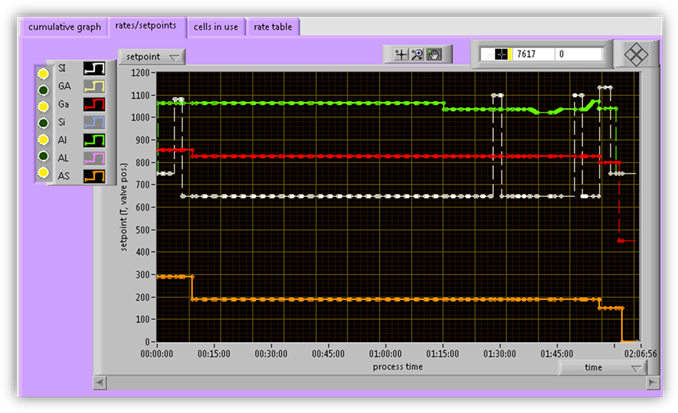

MBE growth process control and data acquisition software was developed in-house by Dr. Enrico Segre in the Physics Core Facilities at the Faculty of Physics (WIS). This powerful software features a user-friendly interface, high flexibility and allows accurate system calibration, comprehensive on-line control, and fully automatic implementation of a growth process. Most importantly, the format of growth sequence protocols, versus commercially available MBE software, are fully 'transparent' for wafer users, allowing straightforward band-gap analysis and simulations for proposed heterostructure devices.

MBE growth process control and data acquisition software was developed in-house by Dr. Enrico Segre in the Physics Core Facilities at the Faculty of Physics (WIS). This powerful software features a user-friendly interface, high flexibility and allows accurate system calibration, comprehensive on-line control, and fully automatic implementation of a growth process. Most importantly, the format of growth sequence protocols, versus commercially available MBE software, are fully 'transparent' for wafer users, allowing straightforward band-gap analysis and simulations for proposed heterostructure devices.