Sputter is the main apparatus used in our group. It is used to produce high quality ceramic & metallic thin film.

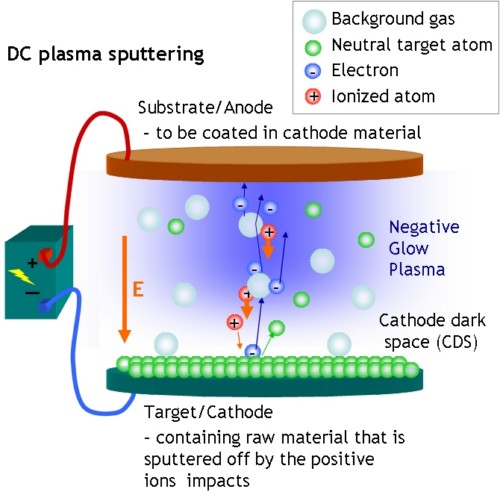

Sputtering is a process whereby atoms are ejected from a solid target material due to bombardment of the target by energetic particles. Sputter deposition is a physical vapor deposition (PVD) method of depositing thin films by sputtering, that is ejecting, material from a "target", that is source, which then deposits onto a "substrate".

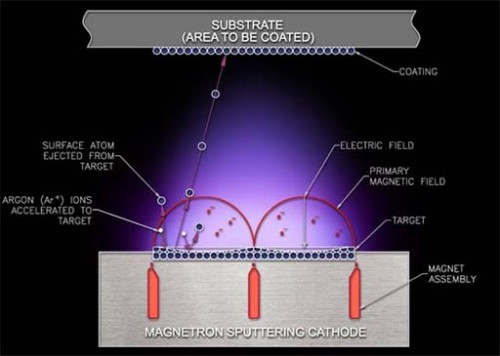

Magnetrons are used to create plasma and the energetic particles. We use DC mode for metals deposition (<1000W) and RF mode for ceramics (<500W). Argon and oxygen gases are utilized as sputtering gases.

Metal targets deposited in presence of oxygen gas give metal oxide films. This method is called reactive sputtering. We use this method to deposit MgO & Ta2O5 films using Mg & Ta metal targets.